Things are changing in the marine fiberglass molding sector. Methods are slowly - albeit surely - moving from open-mold methods (smelly, messy, high in chemical emissions) to closed-mold infusion (or vacuum infusion process, VIP), a safer, more effective way of molding fiberglass.

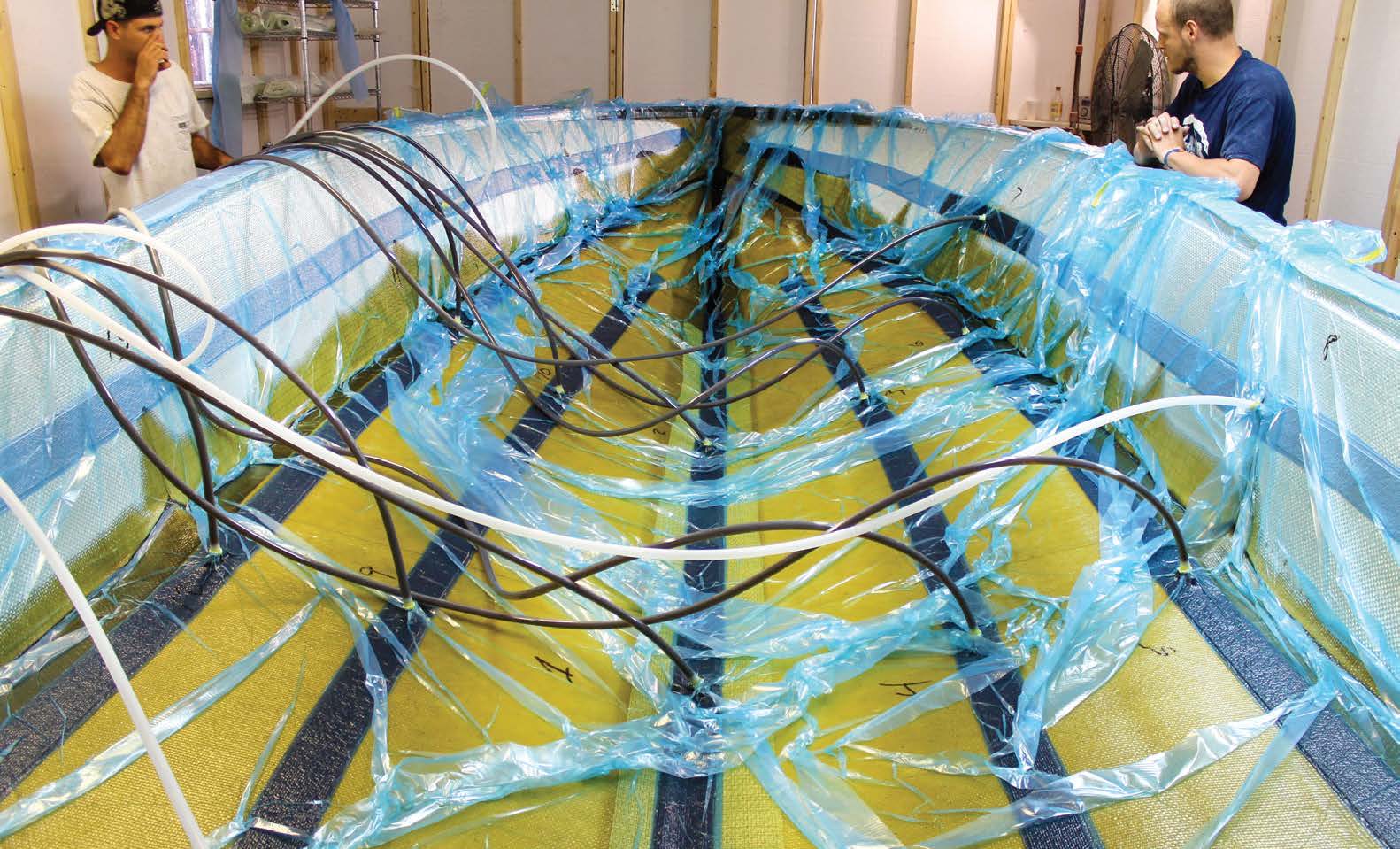

To give a brief idea of how this works, first a mold is coated with a wax coating. Then fiberglass mats are layered on, using a specially formulated infusion molding adhesive to hold the mats in place. Enter: TensorGrip M30 Infusion Molding Adhesive. When the layup is complete, a plastic bag or cover is attached to the edge of the mold and sealed in place. Then tubes for resin infusion and vacuum suction are attached strategically around the mold to saturate the fibers and remove any airspace, forming a strong, evenly saturated part.

So why is the vacuum infusion process revolutionizing the boat-building industry? Because of the science of it, the finished product is much lighter and stronger than traditionally open-molded parts. This is because the ratio of fiber to resin is approximately 35/65 as opposed to the 65/35 ratio achieved by open-molded methods.

Not only that, but the emergence of tightening environmental regulations can also be satisfied with the closed-molding/vacuum infusion process. Simply because of the nature of the method, VOCs and HAPs are contained and less styrenes (a closely monitored chemical) are released into the atmosphere.

So what about TensorGrip M30? Where does it fit?

M30 is what holds the process together - literally. This adhesive has been specifically designed to safely secure fiberglass mats in place as the resin is infused. This eliminates the risk of wrinkling or moving. Then, as the resin is infused and air is removed, M30 changes state and becomes part of the cured polyester or vinylester matrix.

And what sets TensorGrip M30 apart from other infusion molding adhesives?

Unlike many other competing products, the M30 is a fine, even mist spray to ensure full coverage while still allowing the resin to saturate the layup effectively. Not only that, but because of the chemical formulation, it effectively crosslinks with the infused resin to form a stronger final chemical composition.

Want to know more? See us at the Miami boat show, February 12-16, 2015; booth 4089.

Be gripped by the awesome power of Tensor. Outperform again!

![]()