TensorGrip® TC Adhesives has combined its understanding of the challenges faced in composites processes to develop a revolutionary adhesive system. TensorGrip®TC60 has been acutely engineered to meet the demands of composite core material bonding in infusion layup, yielding optimum results.

We are proud to add to our growing line-up of high-performance composites adhesives with a solution that offers unprecedented ease-of-use and time savings. The unique properties of TC60 mean that substrates including PU Foam, PET & PVC core board materials can be securely fixed into the build up - whether on a horizontal or vertical plain - allowing for the highest possible quality of build up before resin infusion and eliminating the requirement for mechanical fixings.

Let’s take a look at some of the unique benefits of TensorGrip® TC60:

- Unique formulation: TC60 has been developed with a unique and innovative formula which is proven to succeed in core foam bonding in the infusion dry lay up process. Whilst this adhesive offers ultimate value when bonding ‘stringers’ into boat hulls, it’s also suitable for wood-based core material bonding (please note TensorGrip® TC60 is not for general glass fibre mat layup).

- Enhanced productivity: We’re transforming infusion layup processes with TC60, which enables core foam detail items to be infused within the main structure where a secondary wet lay process may have previously been needed. This is highly beneficial in infusion layups where there is a need to accurately position core foam materials onto vertical faces. This means less time spent in wet lay and even more time savings in production efficiency.

- High tack, fast flash: TC60’s high tack, fast flash and sheer adhesive performance makes it an ideal solution for foam core bonding. When you choose this adhesive, you can proceed in confidence that your material will remain in place, rather than having to rework or repeatedly fix materials which may have been released before layup completion. Flash off in only 2-3 minutes!

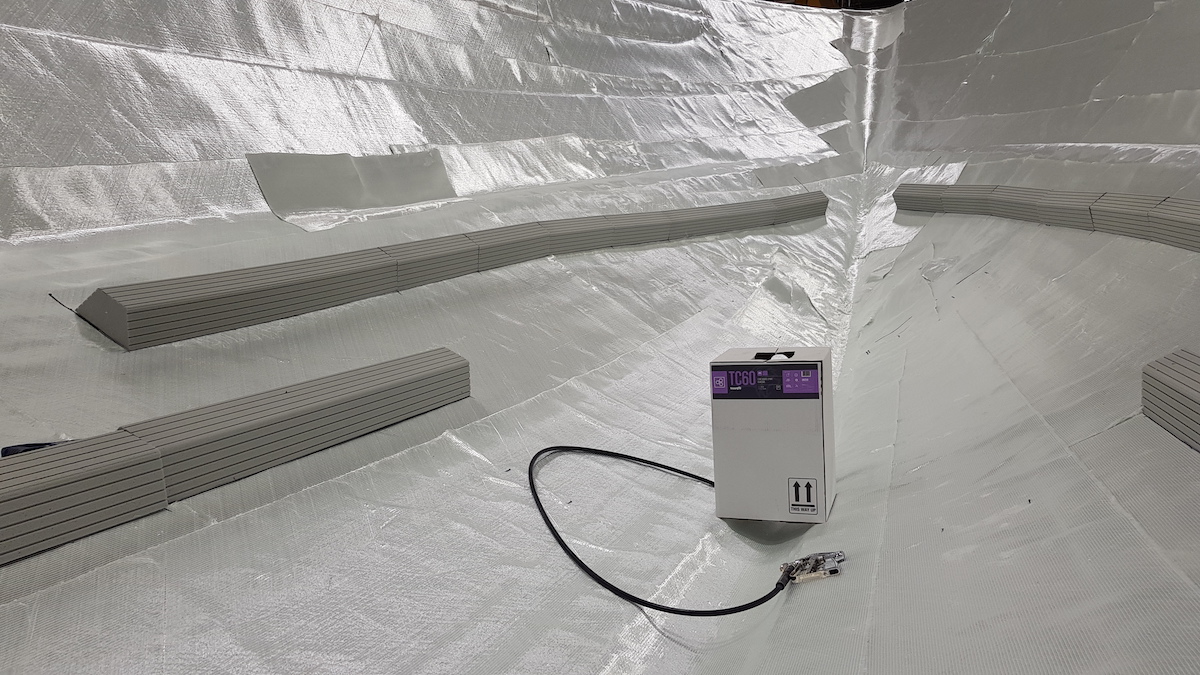

- Unrivalled application: TensorGrip® TC60 is currently available in our canister & gun system, dispensing its adhesive solution via an innovative web spray pattern. Whilst this spray pattern yields a tougher bond that is suitable for high demand vertical face bonding, our ergonomically designed system allows for more comfortable work

TensorGrip® TC60: Unrivalled Composite Bonding Results

We’re redefining convenience in composites processes, with TC60 currently available in 22L Spray Canister Systems. To ensure your experience with TC60 gets off to the best possible start, we’ve shared some TensorGrip® tips on mastering your application:

1. Before you get to work with TC60, ensure that surfaces are clean and free from dust, etc. For best results, the temperature of TC60 and the surfaces being bonded should be between 16˚C - 27˚C).

2. Spray TC60 about 15-30 cm away at a 90 degree angle to the surface, applying a uniform, even coat of adhesive to obtain 60% to 80% coverage of the surface. If necessary, spray another coat of adhesive in areas that appear to need more adhesive.

3. TC60 works as a contact bond so it is necessary to spray both surfaces to be bonded, one surface vertically and the other surface horizontally.

4. Allow 1 - 2 minutes for the adhesive to tack off until no adhesive transfers to the knuckle when touched. Adhere surfaces and press together with adequate pressure.

TensorGrip® TC60: Get Yours

Need an adhesive system that holds composite materials in place successfully? TC60 will perform like no other. To get your hands on this advanced adhesive, get in touch with our sales team or contact UK Category Manager Darren Hill via darren.hill@quinglobal.com or EEMEA & Russia Category Manager Mark Berry via mark.berry@quinglobal.com.