TensorGrip. The world's leading brand in pressurized spray contact adhesive. TensorGrip signifies canisters to a lot of people. That being said, there are a few things that are always good to remember so you can get the best performance out of your glue.

Connection

The key to starting off spraying adhesive right is to be sure your gun, hose and canister are connected correctly.

- Screw the larger hose nut to the gun thread (clockwise) and fully tighten with a wrench. Check hose is securely attached.

- Screw the smaller hose nut to the canister (clockwise) and fully tighten with a wrench. Check the hose is securely attached.

- Turn on the valve on the canister counter-clockwise until fully open. Check connections for any leaks and if any occur tighten connections. DO NOT TURN THE CANISTER VALVE OFF UNTIL THE CANISTER IS EMPTY (this is to prevent the adhesive curing in the hose and gun).

- On initial use, or if the product has been standing for more than 12 hours, the hose and gun may require a purge. Do this by pulling the trigger and adjusting the flow by turning the adjustment screw at the back of the gun (counter-clockwise to open and clockwise to close). Dispense and discard adhesive until a consistent spray pattern is achieved.

Maintenance

If you choose to leave the hose and spray gun on the canister, leave the valve on the canister open. Do not disconnect the hose/gun from the canister. Close and lock the spray gun. Be sure to test the spray before you coat the substrate every time you begin bonding, especially if the canister has been sitting for a while.

Check your spray tip. (Tips can get clogged and damaged, causing poor spray performance.) That's why every canister in the US comes with a new tip. If you don't have a new tip handy, try cleaning up the tip with an aerosol of TensorGrip S101 until the opening is clear.

If you remove the hose and are NOT connecting to a new canister, connect hose to canister of cleaning solvent (sold separately) and spray out until liquid is clear which indicates that the hose and gun is clean.

Ideal Spray Conditions

Temperature and humidity play a big part in the speed of adhesive dry time. The warmer and drier the air is where you are spraying, the quicker your glue will dry.

It is also critical to have clean substrates. The parts you are bonding should be free of dirt, dust, grease and oil. Use a brush to remove dust from the surfaces. DO NOT USE MINERAL SPIRITS OR CITRUS-BASED CLEANERS.

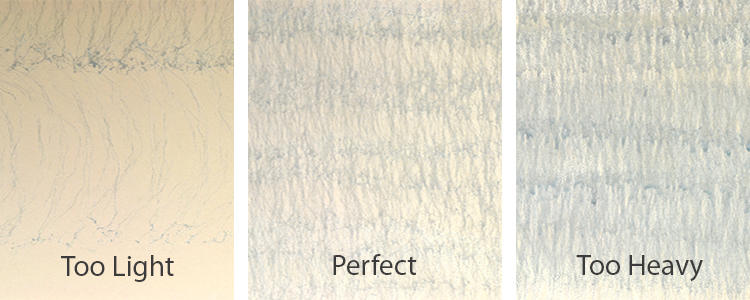

Ideal Spray Pattern

Be sure the spray isn't too heavy or too light. Normal coverage for most products is about 80%. Refer to the product TDS or our Tensor Spray Manual for specific directions. Web spray is shown below.

Disconnection, Disposal/Return

- Turn the valve on the canister counter-clockwise until fully closed.

- Pull the trigger on the gun and hold for at least 10 seconds to expel residual pressure.

- Unscrew the hose nut and disconnect the hose from the empty canister.

- Connect the hose and gun to the new canister.

- Lay the empty canister on its side with the valve pointing AWAY from the operator, and well away from sources of ignition.

- Open the canister valve (counter-clockwise) and release any residual pressure.

- Stand canister upright. Use a hammer and brass punch or other non-sparking instrument to puncture the friable disc.

- As long as the user is able to accept responsibility for de-pressurizing the canister, it can be disposed of as per your normal scrap metal disposal (subject to local waste restrictions).

Get all this & more at your fingertips anytime. Download the Tensor Spray Manual here. And contact us with any other questions!