If you’re ready to upgrade your acoustic panel adhesive offerings, you’re in the right place.

The Tensorgrip® Acoustic line of adhesive sprays was developed for acoustic panel bonding applications. They are endorsed by (and developed with) Autex, making them ideal for bonding acoustic foam panels in different ways, including in-house and on-site bonding processes.

This line includes three main products, each addressing a different need when it comes to fabricating wall panels.

Say hello to the Tensorgrip® Acoustic series

Depending on the type of work needed, each of the three products are formulated differently. You can opt for superior portability, 100% flame-resistance, or full compliance with California’s Volatile Organic Compound (VOC) regulations.

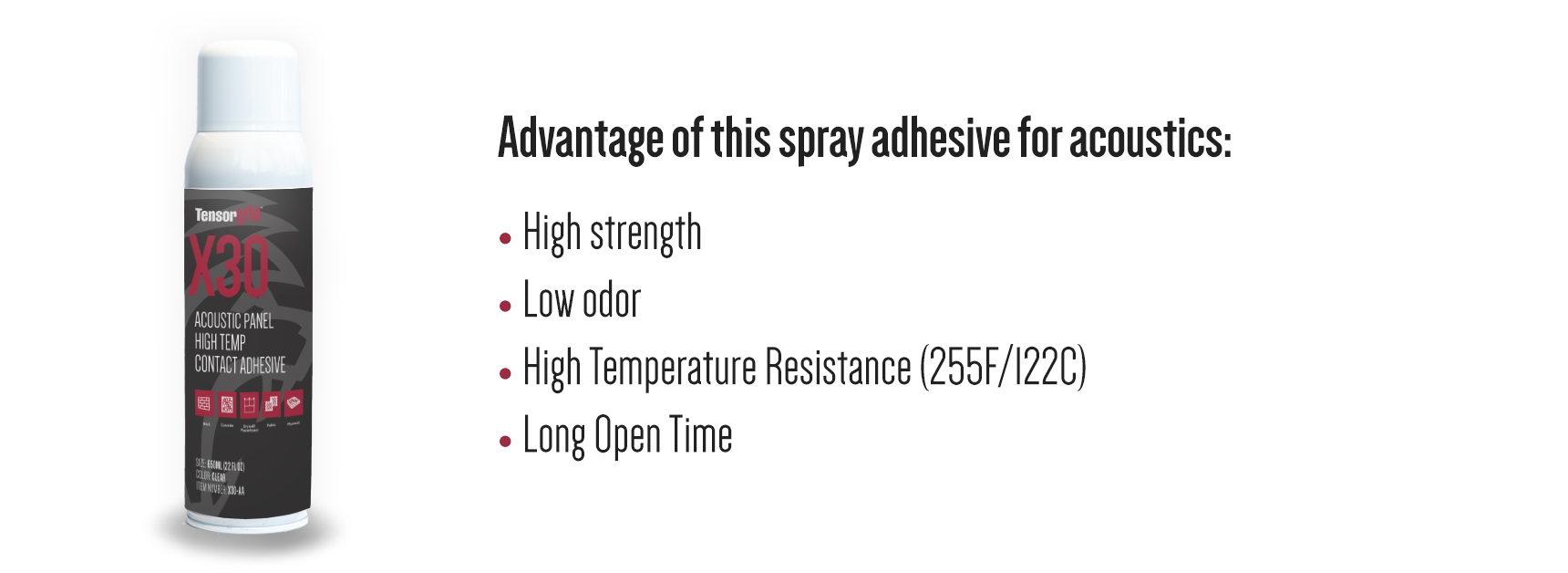

Tensorgrip® X30 — a High Temperature Contact Adhesive for Acoustic Paneling

X30 was designed for excellent adhesion with carpet, thin and thick fabrics, and foam. It has a simple web spray application process, and is packaged as a small aerosol can for maximum portability.

Once sprayed, it dries in 2-3 minutes for fast tack times, but with a 40 minute open time, you’re able to create a serviceable bond in a much more flexible timeframe. It’s designed to provide fast and convenient adhesion while still providing a high tack level for excellent bond.

X30 is available in green or clear variations and gets great results in all types of acoustic panel installation.

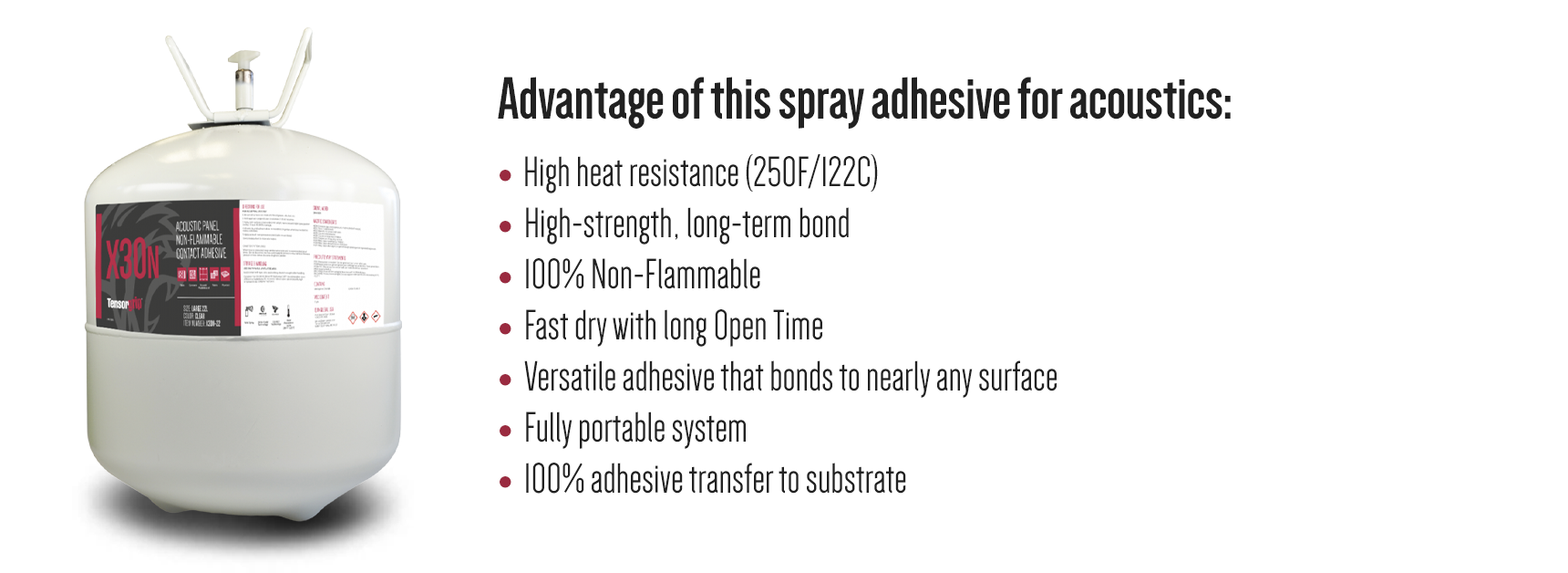

Tensorgrip® X30N — a Non-Flammable Contact Adhesive for Acoustic Paneling

X30N is the larger and more advanced variation of X30, created as a 22L option for larger jobs, and with some small differences, including ZERO-FLAM technology.

Like its smaller counterpart, X30N was designed for great adhesion with carpet, thin and thick fabrics, and foam. It also provides superior adhesion to brick, concrete, drywall, and plywood.

It has a simple web spray application process, and is packaged as a small aerosol can for maximum portability.

With ZERO-FLAM Technology, X30N has a unique propellent system of 100% non-flammable gasses to ensure workplace fire safety, helping protect workers and avoid damage to structures and supplies.

This adhesive is also developed with CO-REZ Technology, a powerful formulation with a specialized resin and gas matrix. This translates to better coverage and a lighter canister to carry, in spite of its larger size.

Tensorgrip® X60 — a California-Compliant Contact Adhesive for Acoustic Paneling

Our X60 adhesive is made for strong versatile adhesion, providing high tack for concrete, drywall, insulation, brick, plywood, and fabrics. X60 stands out from our other acoustic adhesive options because it’s compliant with California regulations (SCAQMD Rule 1168), with a low VOC to meet the strictest standards for toxicity!

Much like X30N though, this X60 adhesive uses the specialized resin and gas matrix in CO-REZ Technology, providing better web spray coverage and a more lightweight canister relative to its size.

With X60, you get the benefit of a long open time ( up to 20 minutes), reaching its full strength in 24 hours.

Conclusion

Between X30, X30N, and X60, this family of acoustic foam panel adhesives provides superior tack strength across a wide range of difficult surfaces, making it the perfect set of products for any acoustic paneling needs.

Depending on your needs, you can go for maximum portability and flexibility with X30, maximize flame resistance on larger jobs with X30N, or ensure full compliance with California regulations when you use X60.

Even if you choose to supply just one of the three, you can list it with confidence!

Learn more about each of these acoustic adhesives on their respective product pages:

To request a sample or information on any of our products, please contact our team!