In a busy joinery workshop, it’s smart to stick to what you know – right? Experimenting with new products or going from one brand to another and back again can lead to faulty product ending up on the waste pile – or worse, faulty product going out to market, with consequences for your reputation.

If your current adhesives are working for you – and we mean REALLY working, delivering efficient, seamless performance – then there’s no need to fix something that isn’t broken. But if you’re sticking with your current brand purely due to fear of the unknown, or worries about having to retrain your team, then you could be holding your business back.

Joinery manufacturing is a numbers game. Lean manufacturing processes are essential for protecting your profit margin – and underperforming adhesives are a great way to ensure your workshop is anything but lean. No matter how experienced your team is, manually-applied adhesives leave room for human error that can cost you dear.

Conversely, switching to Tensor Joinery adhesives is a zero-risk strategy. Efficient, easy to use and safe, our adhesives allow joiners to work faster and achieve better results than anything else on the market. Here are six great reasons to choose Tensor:

1. Consistently superior performance

There’s a reason Tensorgrip® is a market-leading joinery adhesive across the UK and Europe – it’s because our products deliver on their promises, outperform the competition, and exceed customer expectations every time. Product innovation and testing is at the heart of our business, and we never settle for second best – every Tensor product has been painstakingly developed in response to demand from the market, and stringently tested to ensure it delivers the results our customers demand. We’re proud to say that Tensorgrip® is the most certified brand of spray adhesive in the world, bearing various British and European certifications including the IMO WheelMark and a British Standard of Bond Strength. We’ve collaborated with some of the world’s leading brand names in solid surface and laminates including Corian, Formica, Westag and more – an indication of the esteem in which our products are held throughout the industry at large.

2. Specialist products for every application

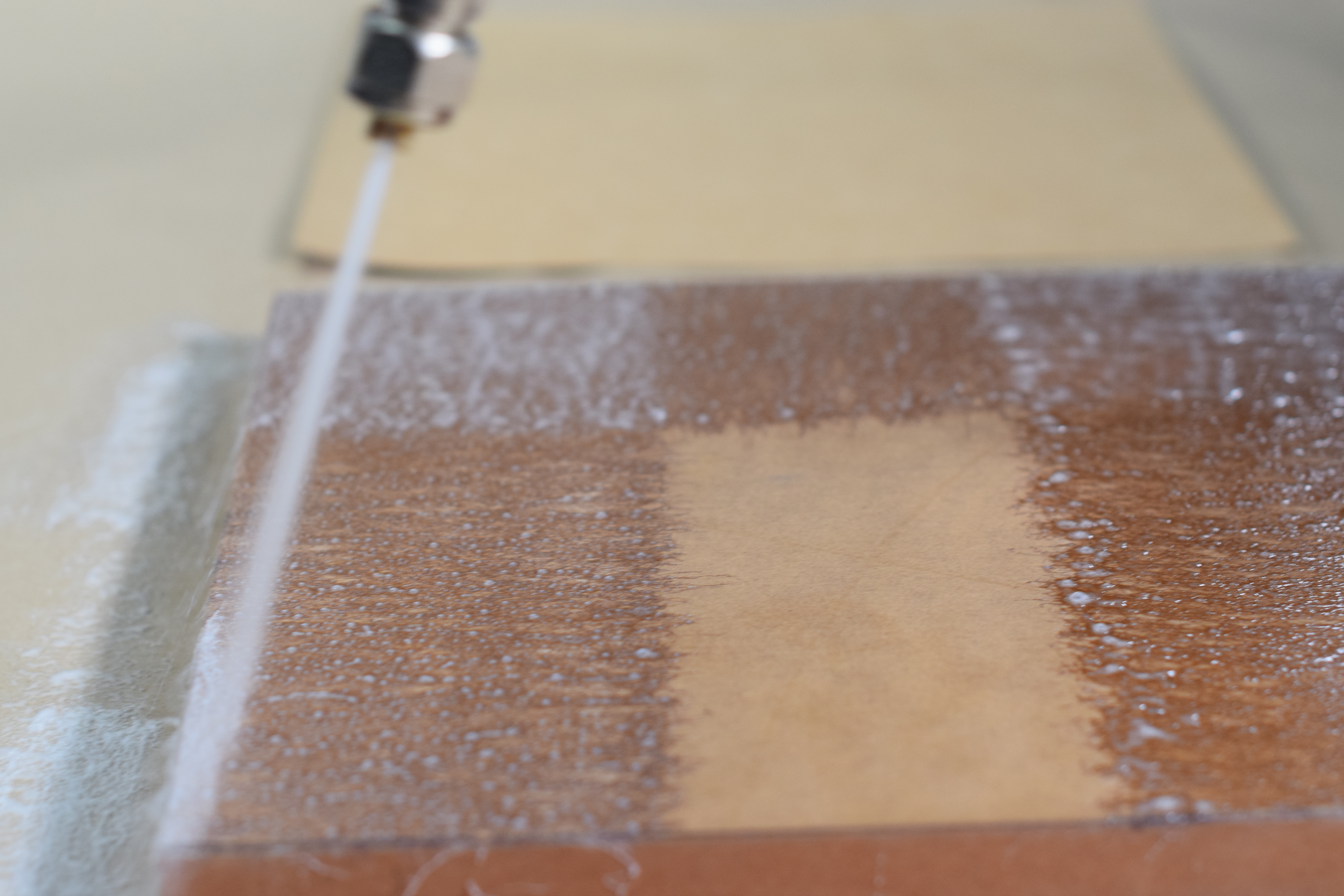

Tensorgrip® offers the most comprehensive range of spray adhesives for the woodworking/joinery industry. We have products specifically designed to meet the challenges of bonding different decorative materials such as laminate, solid surface, veneer, and sheet metals to a wide range of substrates including MDF, plywood, OSB, MFC, and more.

In addition to this, we have product specifically adapted to almost every environment that requires joinery – from heat resistant adhesives suitable for demanding environments like kitchens and industrial settings, to marine adhesives that can cope with the elements as well as complying with strict regulations, to super-strong adhesives designed for construction tasks. View a copy of our brochure here.

3.Leading on safety

Awareness is growing about the importance of safe working in every industry, and joinery is no different. Tensor Adhesives supports businesses to safeguard their workforces in a number of ways. Firstly, our spray application system offers a more ergonomic alternative to manually-applied adhesives, with less stooping, reaching and bending required to achieve a uniform application. This helps avoid issues like repetitive strain injuries, which are a major contributor to loss of productivity and earnings.

Secondly, and more importantly, we’re leading the way on safer adhesive formulations, innovating to eliminate harmful chemicals like dichloromethane from our products whenever possible, and working with our customers to raise awareness about respiratory health in the workshop.

4.Cost-effective

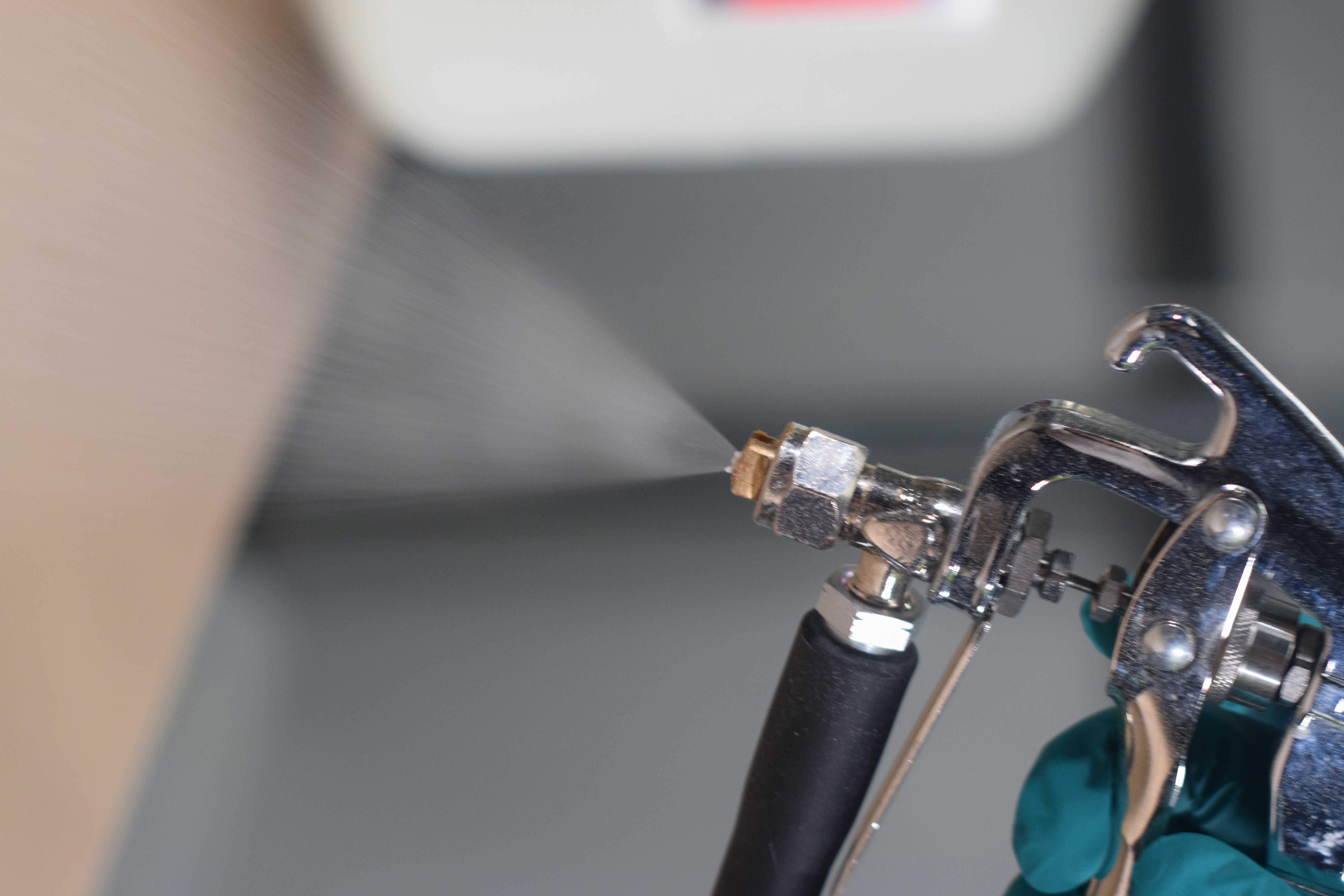

Applying adhesive by hand using a brush, roller or trowel is a messy, time-consuming and wasteful task. Adhesive goes where it’s not supposed to go – and sometimes vice versa, which can result in costly bond failures. Tensor’s spray application system ensures cost-effectiveness by delivering a consistent, project-specific coat weight on every single job, eliminating human error and reducing waste. Our pressurised canisters are designed to dispense every last drop of product for ultimate value for money.

5.Multi-format versatility

Working on a large surface lamination job? Our 22-litre canister with its proprietary spray wand or gun has all your needs covered. Need to get into a tight corner, or do some spot repairs? Reach for our 500ml aerosol canister. Every one of our adhesive products is available in both formats, so you never have to compromise on your preferred adhesive, regardless of the job at hand.

6. Advanced technical support

Looking for advice on which adhesive is right for your business, or for a specific project? Maybe you’ve run into difficulties with your existing adhesive and you’re looking for an alternative? We’re a UK business with UK customer support and a dedicated technical team with unrivalled expertise in the world of adhesives. Our products are backed by a comprehensive database of technical and compliance information, available to download at your convenience. And if you need to speak to a real human about a challenge you’re facing, we’re only too happy to help.

To find out more about our product range, locate a stockist, or speak to the team, get in touch!

.png)