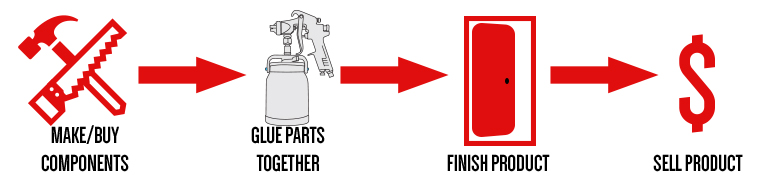

If you’re reading this, we’re guessing that adhesive plays a role in your production line. In fact, we think that your production line looks like this;

Standard contact adhesive can be a bottleneck in the gluing part of this process. By working out the maths, we identified 2 main reasons why;

1. Equipment Maintenance

2. Slow Applications

But First, What Are Bottlenecks?

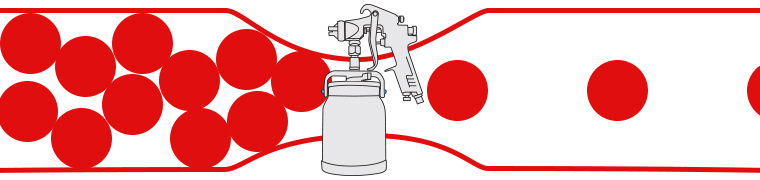

Bottlenecks are the pain points. If you think about a bottle, it has a wide base and narrow neck so the liquid flow is restrained, and doesn’t all come out at once.

If you have a lot of bottlenecks in your production line, they’re hurting how fast you can manufacture your product. That affects the cost you can produce for, your profit margins, how well you can compete, and how much you can keep up with demand.

To put it simply, bottlenecks are inefficiencies.

Equipment Maintenance

Between refilling gun pots, cleaning up and setting up, standard contact can consume up to about 25 minutes each day.

That’s 125 minutes per week and 100 hours a year.

It works out to be 3 weeks out of every year you’re spending plugging in air compressors, filling up gun pots and cleaning out your gun.

Consider how much you produce in a 3 week span. That’s how much, plus more, that you’re missing out on.

Slow Applications

In a recent test, we found out it takes 14 minutes (approx.) for one benchtop to be laminated with standard contact adhesive.

In a full working week of 38 hours minus the 125 minutes that equipment takes up, you have about 36 hours left, not including any breaks.

Take out 30 minutes a day for breaks, and that’s 33 hours each week to glue things together.

In a week you could glue 145 benchtops, in a year; 6,960.

Assuming a monolithic process, it is 20 benchtops per day.

Not exactly a lot, considering you could be bonding more than 40 benchtops per day.

How You Can Eliminate These Bottlenecks?

Choose TensorGrip Canister Adhesives.

TensorGrip Canisters store adhesive in a self-propelling canister that uses aerosol technology.

Equipment

All TensorGrip requires is a canister, gun and hose. Once the canister is opened, it never needs to be closed. Set up takes 0 seconds everyday. You can pick up the gun and get going.

There is no stopping and starting throughout the day to refill the gun. The spray pattern is controllable, so clean up is minimised.

That gives you 35 hours a week to be gluing surfaces together.

Adhesive Application Times

TensorGrip takes approx. 7 minutes to bond a benchtop, half the time of standard contact.

You have, including a break, about 7 hours of gluing time each day with TensorGrip.

7 hours x 60 = 420 minutes each day

420 ÷ 7 mins to bond = 60+ surfaces bonded together in one day.

60 x 5 = 300 in a week

1200 x 12 = 14,400 in a year.

That’s 7,440 more bench tops laminated together in 1 year with TensorGrip.

Of course, this may vary a little depending on what your application is, but it’s still decreasing the amount of time it takes for you to produce products.

That decreases your lead times and the cost of manufacturing while increases your production capabilities and decreases the cost of manufacturing -- minimising bottlenecks in your processes.

Find out more about what specific bottlenecks TensorGrip can help remove for your production line. Contact us today.